I purchased my John Deere 1025R from a JD dealer in Covington, LA back in 2016, and it’s been a reliable machine overall. Most of the issues I’ve encountered have been with the MMM deck, but I’ve been able to work around those. I’ve handled all the maintenance and inspections myself and expected this tractor to be with me for years to come. Unfortunately, that might not be the case.

About a month ago, as colder weather rolled in, the tractor started having trouble starting. Normally, it would fire up after one or two cranks with a small puff of smoke, but it began taking three or four cranks and producing more smoke than usual. I initially blamed the colder temperatures but decided to do some research online. Many suggested that the in-line fuel filter could be the culprit in most cases. Since it was time to replace the fuel filters anyway, I ordered them and kept digging for information.

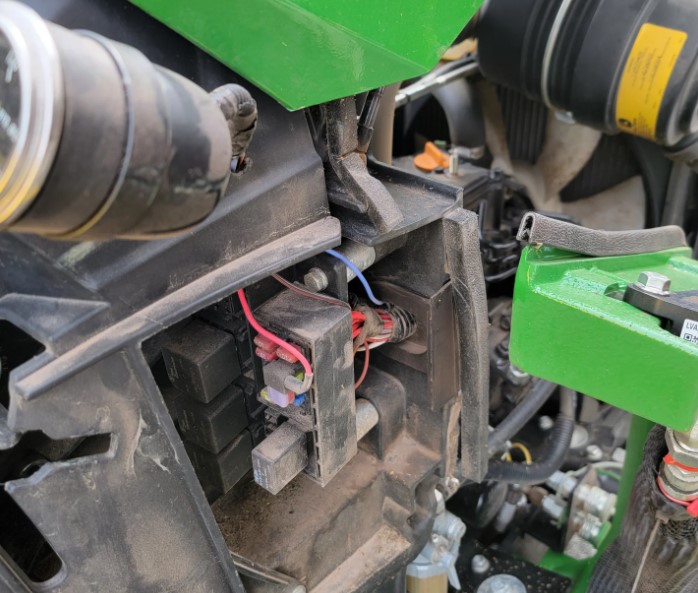

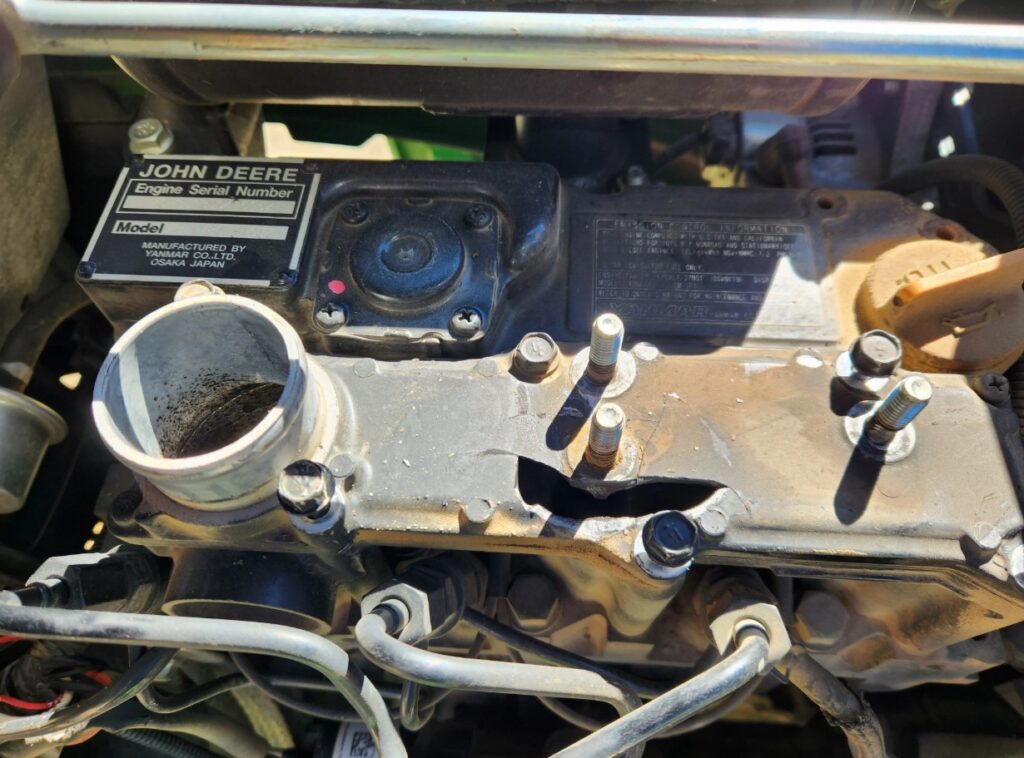

That’s when I came across posts discussing a design flaw with the air filter bracket. It seems the bracket can stress the air inlet cover, potentially causing it to fail and even allowing aluminum fragments to be sucked into the cylinder head and beyond. I hadn’t heard about this issue before, so I checked my tractor. At first glance, everything looked fine, but upon closer inspection, I noticed a slight discoloration on the inlet cover and a small gap near the bracket. When I removed the bracket, I discovered a hole large enough to fit a couple of fingers (photo attached).

I’ve avoided starting the tractor since making this discovery. I contacted my dealer, Sunshine Quality Solutions, last Wednesday, and they initially scheduled the tractor for pickup today (December 20). However, they didn’t show up, and when I called, I was told the pickup was rescheduled to January 5—two weeks later. I also sent an email to JD customer service with a photo and the serial number, and they gave me a tracking number, promising a response within 48 hours. So far, I haven’t heard back.

I never received any notification about this issue—no emails, no letters. I only stumbled upon it while searching online. This seems like an engineering oversight: the inlet cover is made of cast aluminum, approximately 1/8″ thick, and supports about 7 pounds of air filter housing and bracket on a 6-inch lever that’s subject to constant bouncing.

For now, my priority is getting the tractor fixed. I’m hoping the aluminum from the hole simply fell out onto the ground and that I won’t need a new engine. I’m sharing this to document the issue in case others encounter it in the future.

Needing a few extra cranks to start in colder weather is pretty normal. If you had actually lost a cylinder, you’d definitely notice, and if two cylinders were gone, the engine likely wouldn’t start at all. As long as the compression sounds even across all cylinders during cranking, you’ve probably gotten lucky. If you want to be certain, you could always perform a compression test to check the engine’s condition.

If the engine is fine, I’d suggest simply buying the updated air filter kit and intake manifold instead of getting into a drawn-out fight with JD. It’s hard to say whether JD ended the recall on their own or if Yanmar, the engine manufacturer, stopped covering the damages, telling JD they were done dealing with the fallout from this issue. Either way, if your engine hasn’t been harmed, it’s probably not worth the time and effort to pursue the matter.

Now, if there is damage to the engine, I can understand trying to push for a replacement. However, I wouldn’t expect much progress there either, since the engine lasted through the warranty period—even if only by a narrow margin.

Thank you. As mentioned, my goal was simply to document this issue for anyone who might encounter it in the future. I feel it’s important to share this information with the community and ensure that John Deere is made fully aware of the situation. The real issue, in my opinion, lies in the lack of transparency in addressing this problem.

I believe John Deere should have provided formal communication to customers, outlining the serious risks associated with a cracked air inlet cover. As it stands, the only way to learn about this issue is by stumbling upon it online or hearing about it from someone else. When a known design flaw has the potential to cause catastrophic engine failure, owners should be properly informed.