I own a 2012 1025R, and it has always had a slightly rough start, usually accompanied by a few seconds of blue smoke. From what I’ve heard, this seems to be common with 1025s. However, recently, it’s been acting differently. When I start it, the engine turns over but then shuts off. On the second attempt, it struggles quite a bit — shaking violently, producing a lot of blue smoke, the RPMs fluctuating erratically. After about 20 seconds, it finally smooths out and runs perfectly. This behavior is a noticeable change from how it used to start. Any suggestions on what could be causing this? It hasn’t been cold, either — on the last two rough starts, the temperature was around 60°F. Thanks in advance for any advice!

If you’re not consistently adding a high-quality diesel fuel treatment and cleaner to your fuel, it’s something I strongly recommend doing. Diesel fuel quality has declined over time due to supply issues and inconsistent sourcing.

The increased use of biodiesel and higher blend ratios often results in poorer fuel quality. By using a premium treatment and cleaner, you can enhance performance, improve starting reliability, and even boost fuel efficiency. Ultra Low Sulfur Diesel (ULSD), the standard fuel now, lacks the lubricating properties older diesel had. A good additive can restore that lubricity and increase cetane levels, making the fuel more combustible.

Some people claim they’ve never had issues without using additives, but this can be like ignoring heart health until a crisis happens. For the minimal cost of a good diesel treatment, it’s an easy way to reduce risks. Using it consistently is like taking preventive measures to avoid long-term problems.

For cleaning a system that hasn’t been running treated fuel, there are effective products available to clean the entire fuel system. Be ready to replace filters after using a system cleaner, as it can dislodge accumulated buildup. For example, Hot Shot offers good deals on these products, and using them can lead to fewer problems with starting, smoke, or engine performance. Personally, I’ve gone as far as 400 hours between filter changes by consistently using treated fuel in my equipment.

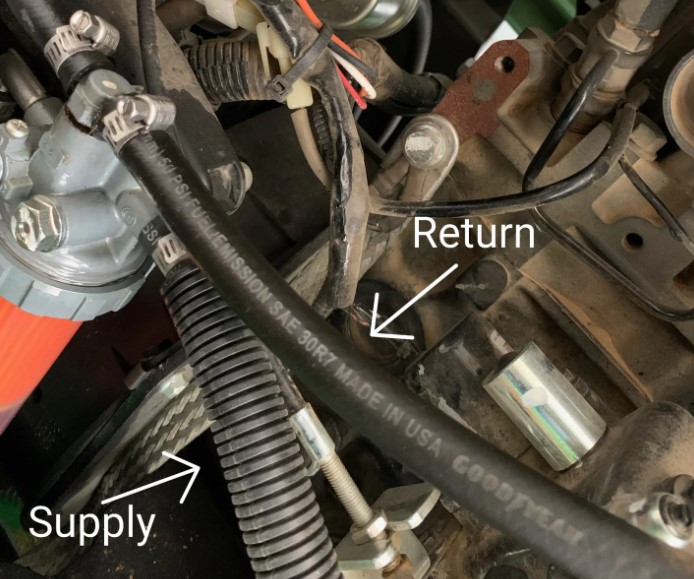

If you’re encountering issues when the temperature is around 60°F or lower, the glow plugs or glow plug relay might be worth investigating. Since the three relays (starter, glow plugs, and fuel shut-off solenoid) are identical, you could swap them around to see if the problem shifts. If swapping causes other systems to fail, you’ll have identified the faulty relay. I’ve experienced failures in both the glow plug relay and the fuel shut-off solenoid, and the symptoms matched what you described—difficulty starting due to glow plugs not energizing. Testing voltage at the glow plugs can confirm whether they’re receiving power when the relay is engaged. I now keep a spare relay handy because replacements from the dealer were more affordable than auto parts stores in my case.

That said, glow plug issues at 60°F are somewhat uncommon. Poor fuel quality might be a bigger culprit. Some biodiesel blends or diesel mixed with recycled cooking oil can severely impact detonation temperature and pressure, leading to similar problems.

For a 2012 tractor with potentially 1,200–1,500 hours, valve lash could also be a factor. While unlikely in machines with fewer hours, it’s still worth considering if other possibilities are ruled out. If the glow plugs are cycled fully at startup, does it make any difference? Did the issue appear suddenly?

To troubleshoot, start with the basics: replace filters, use high-quality fuel or a conditioner, test glow plug voltage, and leave valve lash adjustment as a last resort. Even a single malfunctioning glow plug or a loose connection can cause one cylinder to struggle, leading to these issues. Be sure to check all three plugs thoroughly.